Chaga Mushroom Powder

Chaga Mushroom Powder

MIGU supplied Chaga Mushroom Extract Powder polysaccharide 10%,20%,30%,40%,50%; refined powder and OEM service with analysis meets the EP, USP, JP, CP.....

Chaga Mushroom Powder and extract 10%, 20%, 30%, 40%, 50% polysaccharide by U offered by 17 years experienced cGMP manufacturer with warehosues in China–MIGU

Latin Name: Inonotus obliquus

Material Original:China

Extracted Part: Mycelium

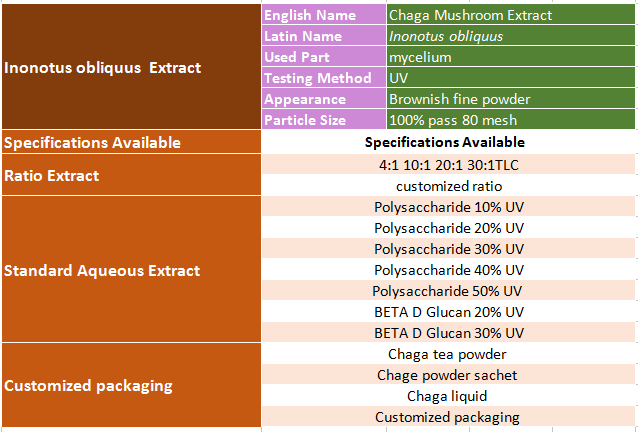

Supported Purity: Polysaccharide10%~50%,4:1~30:1, refined powder

History of Chaga Mushroom Powder (Inonotus obliquus)

Inonotus obliquus,commonly known as chaga mushroom(a latinisation of the Russian term’чага’),is a fungus in

Hymenochaetaceae family,which is often referred to as the”king of medicinal mushrooms”.

It is parasitic on birch and other trees.This black tree fungus has long been respected in Northern Europe

Canada,China,Finland and Russia for its immune boosting qualities.Chaga mushroom tea has played a significant

role in Russian herbalism and Siberian folk medicine for hundreds,if not thousands of years,particularly for its

ability to help humans adapt to cold harsh climates.Inonotus obliquus grows in birch forests of Russia,Korea

North-Eastern China,NorthCarolina mountains and in China.

Specifications of Chaga Mushroom Powder (Inonotus obliquus) from MIGU

Origin of Chaga Mushroom Powder Extract (Inonotus obliquus) –Totally wild 100%Natural!!!

Chaga extract can be considered as healing only if it was manufactured from chaga mushroom picked from living

birch tree.Today,chaga is being grown artificially in many supplier,by fermentation.Fermentation is an artificial

cultivation of mycelium biomass from the mushroom stamm.Extract made from such”chaga”is almost usless

whatever they claim.Only wildgrown chaga has healing properties which chaga is supposed to produce.Our

chaga extract is made exclusively from wildgrown chaga–Getting from Siberian mountains as below area:

Geographically this fungus is mostly found in very cold habitat.It grows very slowly,suggesting it is not a reliable

source of bioactive compounds in the long run.Attempts at cultivating this fungus on potato dextrose agar and

other simulated mediums resulted in a reduced and markedly different production of bioactive metabolites

Secondary metabolites were either absent or present in very different ratios,and in general showed significantly

less potency in submerged cultures of Chaga.Cultivated Chaga furthermore results in a reduced diversity of

phytosterols,particularly lanosterol,an intermediate in the synthesis of ergosteroland lanostanetype triterpene

This effect was partially reversed by the addition ofsilverion,an inhibitorof ergosterol biosynthesis.

Additionally,the bioactive triterpene betulinic acidis completely absent in cultivated Chaga.In nature Chaga

grows predominantly on birchesand birch bark contain up to 22%of betulin.Betulin is poorly absorbed by humans

even when taken intravenously;its bioavailabilityis very limited.However,the Chaga mushroom converts betulin

into betulinic acid,and many internet sources state Chaga’s betulinic acid is bioavailable,even when taken orally

Unfortunately there is no research that confirms this claim.

All of our chaga material gettin from Grand Khingan belong to Siberia mountains owned the biggest virgin forest

In China,riched for the birch tree everywhere as below area

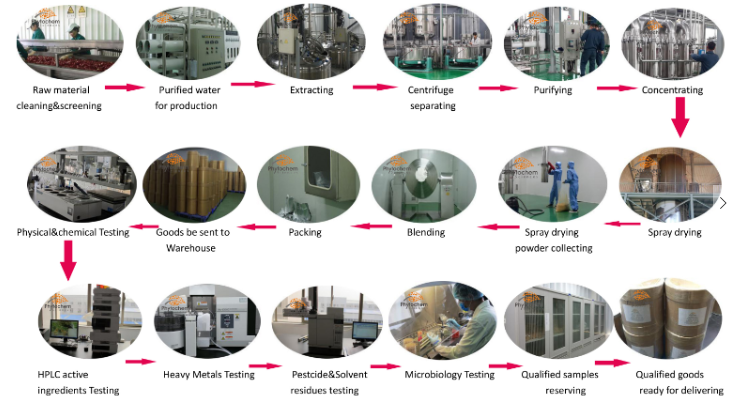

Extraction Processes of Chaga Mushroom Powder (Inonotus obliquus)

Chaga is traditionally grated into a fine powder and used to brew a beverage resembling coffce or tea.For

medicinal use,an extraction process is needed to make at least some of the bio-active components actives are

bioavailable.These biofound in the mostly i ndigestible chitin cell walls of the chaga.Humans lack the enzyme

chitinase,so cannot fully digest raw mushrooms or their derivatives,and the digestive process works too fast for

the stomach acid to take effect.Scientific studies and research are in general also based on highly concentrated

extracts,and traditional Russian usage is also based on a form of hot-water extraction(by preparing zavarka).

extract processing for chaga mushroom powder.png

Currently,three extraction processes are used,each with a different outcome

Hot water extraction is the most common and the cheapest method.Ideally it should be performed under very

high pressure(480 psi/4.0 MPa);boiling will over time cause the bioactive beta-glucans to disintegrate,this is

neutralized by performing this phase of the extraction process under high pressure.

All water-soluble components will be present in the resulting extract.Hot water extraction performed without

high pressure can be compared to a traditional tea-making process;the therapeutic potential will be limited due

to the damage caused by the high temperature,as described above.Water-insoluble components,such as

phytosterol,betulinic acid and betulin,will be absent in a hot water extract.Several extraction rounds combined

with modern pharmaceutical techniques such as alcohol precipitation as a final step can result in high levels of

polysaccharides,up to almost 60%.Theß-D-glucans,the bio-active part of these polysaccharides,might add up to

±35%in a very pure extract.Polyphenolic components are water-solubles and will also be present.Ethanol or

methanol extraction isolates the water-insoluble components,betulinic acid,betulin and the phytosterols.This

extraction process is in general used as a second step after hot-water extraction,since ethanol alone will not

break down chitin effectively-heat is essential.

Fermentation is the most consuming,so is the most expensive;this method is not used very often.time-Because

fermentation methods are not standardized(many types of bacteria and fungi can be used in the process),the

outcome is also not standardized.

Combining the outcome of hot water and ethanol extraction yields a dual extract with all therapeutically

interesting bioactives present in a bioavailable form.Cheap,mass-produced extracts are in general hot water,low

percentage(4-20%)polysaccharide extracts with limited therapeutic value.The information on the supplements’

label will usually reveal inclusion or exclusion of components.However,the majority of mushroom dietary

supplements that are sold are non-extracted,being the cheapest option.To achieve at least some therapeutic

effects the consumer has to make a tea from it.

chaga mushroom powder

Unlike in raw chaga,in chaga extract these biological substances are active,i.e.digestable by our body.Raw chaga

cannot be digested by humans and healing compounds would leave our body without a trace.And”activation”can

be done only through process of extraction either with alcohol or with hot water.When you are brewing tea you

are making something similar to extraction Moreover,extraction process allow to get rid of usless substances and

concentrate healing biological compounds to a very high level.In order to achavie above high purity&digestable

by us,We usually be getting 1kg of chaga extract we use minimum 8kg of raw chaga to keep the high standards&

sustain the premium quality of our chaga extract which different from others!!

References

1.Zheng,W.F.;Liu,T.;Xiang,X.Y.;Gu,Q.(July 2007).“Sterol composition in field-grown and cultured mycelia of

Inonotus obliquus”(PDF).Yao xue xue bao=Acta pharmaceutica Sinica 42(7):750–756.PMID17882960.

2.Jump up^Zheng W,Miao K,Liu Y,Zhao Y,Zhang M,Pan S,et al.(2010).”Chemical diversity of biologically active

metabolites in the sclerotia of Inonotus obliquus and submerged culture strategies for up-regulating their production”.

Appl Microbio l Biotechnol 87(4):1237–54.doi:10.1007/s00253-010-2682-4.PMID20532760.

3.Jump up^Zheng,W.F.(July 2008).“Phenolic compounds from Inonotus obliquus and their immune-stimulating effects”(PDF).

Mycosystema 27(4):574–581.

4.Jump up^Müllauer,Franziska(2011).“Betulinic Acid Induced Tumor Killing”(PDF).

5.Jump up to:abPaper with background on extraction processes

6.Jump up^Matsunaga,Yui,et.al.(2014).“Hot compressed water extraction of polysaccharides from Ganoderma lucidum

using a semibatch reactor”.Asia-Pacific Journal of Chemical Engineering 9(1):125–133

7.Jump up^Rhee,S.Y.(2008).“A comparative study of analytical methods for alkali-soluble β-glucan in medicinal mushroom

Chaga (Inonotus obliquus)”.LWT-Food Science and Technology 41(3):545–549.doi:10.1016/j.lwt.2007.03.028.